Posted by BNTECHGO on 5th Jul 2024

What is FEP Teflon Wire?

In modern industrial and technological fields, selecting the right materials for electrical wires is crucial for the performance and safety of equipment. Traditional wire materials may not be adequate in environments with high temperatures, strong corrosiveness, or where long-term stability is needed. FEP Teflon Wire, renowned for its excellent heat resistance, corrosion resistance, and superior electrical insulation, stands out in such cases.

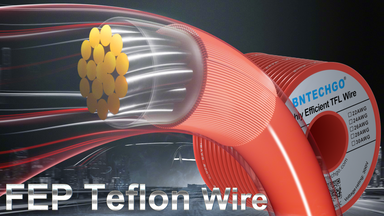

FEP Teflon wire consists of a conductor made of tinned copper and an insulation layer of FEP (fluorinated ethylene propylene)

Tinned copper is a conductor treated with a tin plating on the surface of the copper. This treatment protects the copper from direct contact with air and water, delaying or preventing the formation of verdigris (copper rust), which helps maintain the appearance and integrity of copper products. By improving electrical connections, tin plating also provides a better electrical contact surface, reduces contact resistance, and ensures the reliability and stability of electrical connections.

The insulation layer, FEP, a copolymer of tetrafluoroethylene and hexafluoropropylene, is a high-performance fluoroplastic

Fluoroplastics, polymers containing fluorine, typically exhibit excellent high-temperature resistance, chemical corrosion resistance, and electrical insulation properties due to their unique molecular structure. They also have a low friction coefficient and are non-flammable, making them suitable for many demanding applications. The unique manufacturing process and component ratio of FEP maintain high performance while providing good processability and flexibility. Thus, Teflon wire performs well in various harsh environments and is widely used in electrical connections and transmission in fields such as aerospace, automotive manufacturing, medical equipment, and high-frequency electrical connections.

Features and Advantages of FEP Teflon Wire

- Heat Resistance: FEP Teflon wire can operate stably over a wide temperature range from -65°C to +200°C. Its excellent heat resistance maintains superior performance even under extreme temperature conditions, making it suitable for applications in aerospace, automotive industries, and high-temperature industrial equipment that operate in high-temperature environments.

- Electrical Insulation Performance: FEP Teflon wire has a very low dielectric constant and dielectric loss across a broad frequency range. Even in high-frequency signal transmission and high-precision electronic equipment, FEP Teflon wire provides stable electrical insulation, making it an ideal choice for communication equipment, computer cables, and other high-frequency applications.

- Chemical Resistance: FEP Teflon material is highly resistant to most chemicals, including strong acids, strong bases, and organic solvents. This chemical resistance makes FEP Teflon wire very suitable for use in chemical industries and laboratory environments, ensuring the long-term reliability of the wire in corrosive environments.

- Low Friction Coefficient: The surface of FEP Teflon material is very smooth and has a low coefficient of friction. This characteristic makes FEP Teflon wire perform excellently in applications requiring low friction and anti-adhesion, such as in mechanical equipment, where FEP Teflon wire can reduce frictional losses and extend the lifespan of the equipment.

- Non-Flammability and Weather Resistance: FEP has self-extinguishing properties and is not easily flammable, increasing its suitability for applications with high-security requirements. Moreover, FEP is highly tolerant to ultraviolet light and climate changes, making it suitable for long-term exposure in outdoor environments. Examples include outdoor cables and antenna systems, where FEP wire can withstand harsh climate conditions.

- Biocompatibility: FEP material is non-toxic and has good chemical inertness. It is used in industries and electronics where high temperature resistance, chemical corrosion resistance, and high insulation performance are needed.

Main Application Areas

Aerospace:

FEP Teflon wire is extensively used in the aerospace field. Its excellent heat resistance and electrical insulation performance ensure the reliable operation of cable systems under extreme temperatures and harsh environments, meeting the high standards required for aircraft and spacecraft.

Medical Equipment:

In medical devices, FEP Teflon wire is widely used due to its biocompatibility and resistance to high-temperature sterilization. FEP wire is used in catheters, pumps, and other critical components, ensuring the safety and reliability of the equipment.

Chemical Processing:

FEP Teflon material is highly resistant to most chemicals, including strong acids, strong bases, and organic solvents. This chemical resistance makes FEP Teflon wire highly suitable for use in chemical industries and laboratory environments, ensuring the long-term reliability of the wire in corrosive environments.

Semiconductor Manufacturing:

In the semiconductor manufacturing process, FEP Teflon wire is widely used due to its purity and chemical corrosion resistance. It performs excellently in manufacturing equipment requiring high purity and temperature resistance, ensuring high quality and efficiency in semiconductor production.

Summary

With its outstanding heat resistance, electrical insulation performance, chemical resistance, low friction coefficient, non-flammability, weather resistance, and biocompatibility, Teflon wire plays a crucial role across various industries. Its versatility and high performance ensure reliability in numerous demanding applications. If you are looking for a high-performance wire that can operate reliably under extreme conditions, FEP Teflon wire is undoubtedly your best choice. These characteristics make Teflon wire the preferred choice for electrical connections and transmission in various harsh environments, providing reliable solutions for modern industry and technology fields.

We hope this blog post has given you a better understanding of BNTECHGO FEP Teflon wire. For more information about our products and services, please feel free to send an email to support@bntechgo.com, visit our website at bntechgo.com, or follow us on YouTube, Facebook, TikTok, LinkedIn, and Instagram. We look forward to connecting with you.

For article reprints, please cite the source.